An Engineering Demonstrator—Single Leaf Bascule Bridge with a Truss Span

Examples of real-life engineering are so prevalent that we can fail to notice or appreciate them. This home-made demonstrator can be used to introduce ‘Engineering’ in simple terms.

The demonstrator reflects the disciplines of Civil and Structural Engineering, Mechanical Engineering, Electrical Engineering and Electronic Engineering. With a slight stretch of the imagination, it could reflect other engineering disciplines also, e.g. Building Services Engineering, where the truss span could be a moving duct in a system where ventilation air is to be diverted.

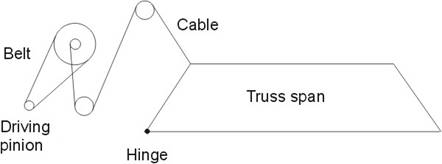

This is the basic arrangement of the demonstrator

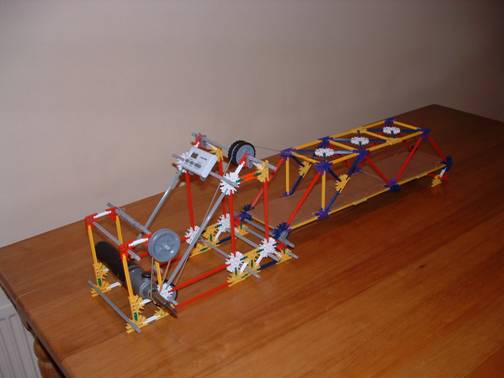

The working prototype is built mainly from plastic-construction-set components. The bridge deck is of corrugated cardboard. The power unit, with a forward and reverse switch, is a rechargeable electric screwdriver that contains a built-in battery, a motor and a gearbox. An electronic timer (representing Electronic Engineering) is provided so that the lifting and lowering times of the span can be measured. In a real bridge a lot more can be achieved by the use of electronics. The shaft of the electric screwdriver serves as the driving pinion. The drive belt is an elastic band. The entire demonstrator can readily be stowed within a box measuring 65 cm × 28 cm × 28 cm, after unclipping the hinge pin.

A rechargeable electric screwdriver provides the

motor and,

as can be seen in the photograph, a planetary gearbox.

Here the bridge is

in the closed position.

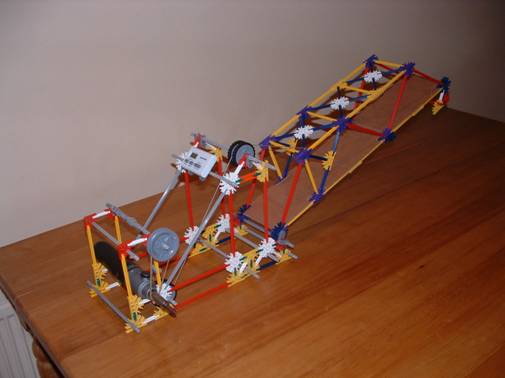

No power

is consumed.

The bridge can remain open in any position without

power. What happens if the motor is not stopped

when the span reaches the highest position?

How are all the parts of the model manufactured?

How

would the parts of a full-size bridge be manufactured?

The raising and lowering times are different. Why?

There are multiple examples of mechanical advantage.

The Tower Bridge in London is a double leaf bascule bridge.

Video Demonstration

You can watch the demonstration by clicking on the image below.

© Jim McGovern 2006–2009